Polyurethane Paint and Primer

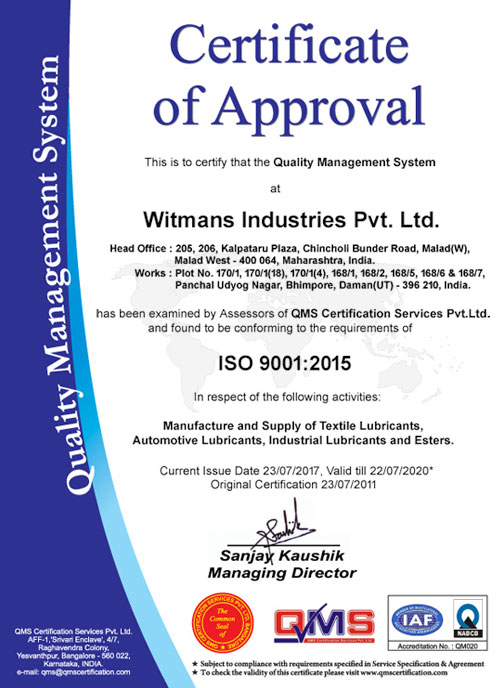

Witmans Industries PVT. LTD. is a one of the leading manufacturer and supplier of Specialty Chemicals in India. We offer products like specialty lubricants, process oils, plasticizers, industrial paints, spin finishes, and textile conning oils, including polyurethane paint and primer which are a types of coatings used to protect and decorate surfaces, made from polyurethane resin. They provide a durable and glossy finish, resistant to abrasion, chemicals, and weathering, making them suitable for various applications such as automotive, marine, and industrial.

These polyurethane paint and primer are manufactured by blending polyurethane resin with solvents, additives, and pigments. The mixture is carefully formulated to achieve desired properties such as adhesion, flexibility, and durability. Once mixed, the paint and primer are applied to surfaces using brushes, rollers, or sprayers and allowed to cure, forming a tough and protective layer.

| Product Details | |

| Surface Finish | Smooth |

| Storage | Room Temperature |

| Application Method | Brush |

| Texture | Smooth |

| Physical Form | Liquid |

| Raw Material | Polyurethane |

| Application | Industrial |

| Purity(%) | 98% |

| Color | Colorless |

| Minimum Order Quantity | 10 Liter |

| Supply Ability | 1000 Liter Per Week |

| Delivery Time | 3-4 Days |

Technical Specification

| PROPERTIES | SPECIFICATION | NOTE |

|---|---|---|

| Finish | Smooth & Semi Glossy to glossy | |

| Application Viscosity @ 30°C | 20-25 Sec | By B-4 Ford Cup |

| Shade | According to the requirement of the | |

| Volume Solid % | 40% | |

| Theoretical Spreading | 8-11 | M2/Ltr@ 35-45 Microns |

| Flash Point | Above 25 0C | Abel Closed Cup |

| Dry to touch | 60-90 minutes | At 30°c |

| Hard Dry | 16-18 hrs. | |

| Fully Cured | 6-7 days | at 30°C |

| Shelf Life | 6 months from mfg. date | Months at 30°c |

Application Details:

Base: 4 parts by volume

Mixing ratio: Curing agent- 1 part by volume

Pot Life: 4-6 hours at 30°C

Application method: Air spray/brush

Recommended thinner: Witcoat P.U. Thinner

Film thickness (dry): 35-45 microns (by dft meter)

Surface Preparation:

Remove oil grease with suitable detergent solution and other contaminants by high pressure fresh water hosing. Dust off the residue.

Application Conditions:

Apply only on a dry and clean surface, with a temperature above the dew point to avoid condensation.

Preceeding Coat:

Witcoat epoxy z/p primer, Witcoat Polyurethane Primer or as per specifications.

Subsequent Coat:

Witcoat Polyurethane Paints or as per specifications.

Remarks:

Hardener is sensitive to moisture and hence needs to be stored in a dry place. Keep the can tightly closed after use. After exposure in a contaminated environment, clean the surface with high-pressure fresh water hosing and allow it to dry before applying an overload. If the maximum recoat interval is exceeded, roughen the surface to ensure intercoat adhesion.

Safety:

As a general rule, inhalation of solvent vapour or paint mist and eye and skin contact with the liquid paint should be avoided. In addition, national and local safety regulations should be followed.

Features

Durability: Provides a tough and resilient coating that withstands abrasion, impact, and weathering.

Chemical Resistance: Resistant to chemicals, oils, and solvents, making it suitable for industrial and automotive applications.

UV Resistance: Offers excellent resistance to ultraviolet (UV) radiation, preventing color fading and degradation.

Gloss and Color Retention: Maintains its glossy finish and color over time, even in harsh environments.

Flexibility: Exhibits flexibility and elasticity, allowing it to expand and contract with substrate movement.

Fast Drying: Dries quickly to form a hard and durable finish, reducing downtime during application.

Adhesion: Bonds strongly to various surfaces, including metal, wood, and plastic, ensuring long-lasting adhesion.

Versatility: Suitable for use on different substrates and surfaces, including exterior and interior applications.

Easy Application: Applies easily with brushes providing a smooth and uniform finish.

Water Resistance: Provides resistance to water and moisture, making it suitable for marine and outdoor applications.

Applications of Polyurethane Paint and Primer

Automotive: Polyurethane paint and primer are applied to vehicle exteriors for a glossy finish that resists weathering and UV exposure.

Marine: Used on boat hulls to protect against saltwater corrosion and abrasion.

Industrial Equipment: Applied to machinery and metal structures for corrosion protection and durability in industrial settings.

Wood Finishes: Used on wooden surfaces to enhance appearance and provide scratch resistance.

Aerospace: Applied to aircraft components for lightweight and durable protection against high-altitude conditions.

Construction: Used on architectural elements for weather resistance and aesthetic appeal.

Electronics: Used as a protective coating for electronic devices and components.

Industrial Machinery: Applied to machinery parts for corrosion resistance and durability.

Flooring: Used as a floor coating for abrasion resistance and easy maintenance.

Decorative Finishes: Used in architectural applications for a glossy and durable finish.

Other Products

Contact Details

CORPORATE OFFICE:

Address:

205 and 206, Kalpataru Plaza, Chincholi Bunder Road, Malad (West), Mumbai- 400064, India.

PHONE NUMBERS:

EMAIL:

Share this: