Die Lubricant

| Product Details | |

| Type | Lubricant |

| Brand | Witcol |

| Application | Industrial |

| Minimum Order Quantity | 10 Liter |

| Supply Ability | 1000 Liter Per Week |

| Delivery Time | 3-4 Days |

Features

Our metal forming lubricants offer the following key features to enhance performance and reliability in various operations:

- High lubricity: Reduces friction and wear between metal surfaces during forming.

- Heat resistance: Maintains lubricating properties at elevated temperatures.

- Anti-sticking properties: Prevents metal parts from sticking to dies and molds, ensuring smooth release.

- Residue-free: Leaves minimal or no residue, facilitating subsequent processes like painting, plating, or welding.

- Compatibility: Works with a wide range of metals and alloys, including aluminum, steel, brass, and copper.

Applications

Witcol DL 81 die lubricants are essential in various industries, enhancing precision in metal forming processes:

- Automotive: Used in die casting and stamping to produce engine blocks, transmission housings, and body panels.

- Aerospace: Applied in manufacturing aircraft engine parts, structural components, and landing gear.

- Electronics: Utilized in making enclosures, connectors, and heat sinks.

Technical Specification

| PROPERTIES | ASTM METHOD | UNIT | VALUES |

|---|---|---|---|

| Appearance | Visual | Attribute | Clear Liquid |

| Colour | Visual | Attribute | Light Yellow |

| Viscosity @100 °C | ASTM D – 445 | CST | 13 ± 3> |

| Density | ASTM D – 1298 | Number | 1.20 ± 0.1 |

| Flash point | ASTM D – 92 | °C | 180 |

| Pour point | ASTM D – 97 | °C | (-) 5 |

| Copper Corrosion Test | ASTM D – 130 | No. | 4 C |

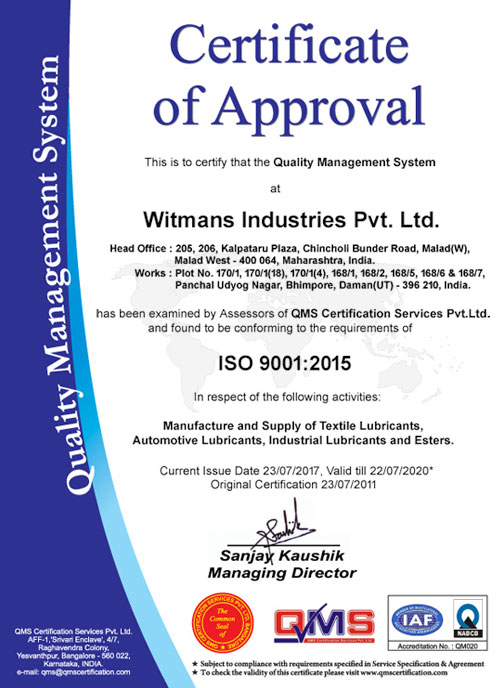

About Witmans

Witmans Industries PVT. LTD. is a one of the leading manufacturer and supplier of Specialty Chemicals in India. We offer products like specialty lubricants, process oils, plasticizers, industrial paints, spin finishes, and textile conning oils, including Die Lubricant under the brand name Witcol, which are a type of lubricating agent used in metal forming processes like die casting and stamping. These lubricant reduce friction, improve product quality, decrease tool wear, and enhance production efficiency.

These die lubricants are manufactured by blending various base oils with additives such as boundary lubricants, extreme pressure agents, anti-wear agents, and corrosion inhibitors. These additives improve lubrication performance, protect metal surfaces, and ensure smooth metal flow during forming.

To learn more about our Die Lubricant products, please contact us.

Other Products

Contact Details

CORPORATE OFFICE:

Address:

205 and 206, Kalpataru Plaza, Chincholi Bunder Road, Malad (West), Mumbai- 400064, India.

PHONE NUMBERS:

EMAIL:

Share this: