Anticorrosive Paints

| Product Details | |

| Surface Finish | Smooth |

| Storage | Room Temperature |

| Texture | Metallic |

| Physical Form | Liquid |

| Minimum Order Quantity | 10 Liter |

| Supply Ability | 1000 Liter Per Week |

| Delivery Time | 3-4 Days |

Technical Specification

| PROPERTIES | SPECIFICATION | NOTE |

|---|---|---|

| Finish | Smooth & Semi Glossy To Glossy | – |

| Application Viscosity @ 30°C | 25-35 Sec | By B-4 Ford Cup |

| Shade | According to the requirement of the party | Visually |

| Volume Solid % | 32 % | – |

| Theoretical Spreading | 9-10 | M2/Ltr @ 30-35 Microns Dry Film Thickness |

| Flash Point | Above 25°C | Abel Closed Cup |

| Drying Time @ 30°C Tack Free Hard Dry | 15-20 Minutes. 2-3 Hrs. | Excellent |

| Shelf Life | 6 Months | Months at 30°C |

Features

Corrosion Protection: Anticorrosive paints form a protective barrier on metal surfaces, preventing exposure to moisture, oxygen, and other corrosive agents that can cause rust and degradation.

Adhesion: These paints adhere strongly to metal substrates, ensuring long-term protection and durability even in harsh environments.

Chemical Resistance: Anticorrosive paints are resistant to a wide range of chemicals, including acids, alkalis, and solvents, providing additional protection against corrosive substances.

Weather Resistance: They offer excellent resistance to weathering factors such as UV radiation, temperature fluctuations, and humidity, maintaining their protective properties over extended periods.

Flexibility: Anticorrosive paints exhibit flexibility and elasticity, allowing them to expand and contract with metal substrates without cracking or delamination, particularly important in applications subjected to thermal cycling.

Quick Drying: Many anticorrosive paints feature fast drying formulations, enabling efficient application and rapid turnaround times in industrial painting projects.

Applications of Anticorrosive Paints

Marine Industry: Anticorrosive paints are extensively used on ships, boats, offshore platforms, and marine structures to protect metal surfaces from corrosion due to exposure to saltwater and atmospheric conditions.

Automotive Industry: They are applied to vehicle chassis, undercarriages, and exposed metal components to prevent corrosion caused by road salt, moisture, and environmental factors.

Infrastructure and Construction: Anticorrosive paints are used in bridges, pipelines, structural steel, and other infrastructure projects to prolong the lifespan of metal structures and prevent deterioration due to environmental exposure.

Oil and Gas Industry: These paints are employed in refineries, pipelines, storage tanks, and equipment used in oil and gas exploration and production to safeguard against corrosion in aggressive environments.

Industrial Machinery: Anticorrosive paints are applied to machinery, equipment, and metal components in manufacturing facilities to maintain operational integrity and prevent downtime caused by corrosion-related failures.

Aerospace Industry: They are utilized in aircraft components, landing gear, and aerospace structures to protect against corrosion in high-altitude and aerospace environments.

Power Generation: Anticorrosive paints are used in power plants, transmission towers, and electrical infrastructure to protect metal surfaces from corrosion caused by exposure to moisture, chemicals, and atmospheric pollutants.

Application Details

Application method: Air spray/brush

Recommended thinner: Witcoat Q.D. Thinner

Film thickness (dry): 35-45 microns (by dft meter)

Surface Preparation: Remove oil grease with suitable detergent solution and other contaminants by high pressure fresh water hosing. Dust off the residue.

Application Conditions: Apply only on a dry and clean surface, with a temperature above the dew point to avoid condensation.

Safety: As a general rule, inhalation of solvent vapour or paint mist and eye and skin contact with the liquid paint should be avoided. Forced ventilation should be provided when working with solvent borne coatings in confined spaces or stagnant air. Even when ventilation is provided, respiratory, skin, and eye protection are always recommended when spraying. In addition, national and local safety regulations should be followed.

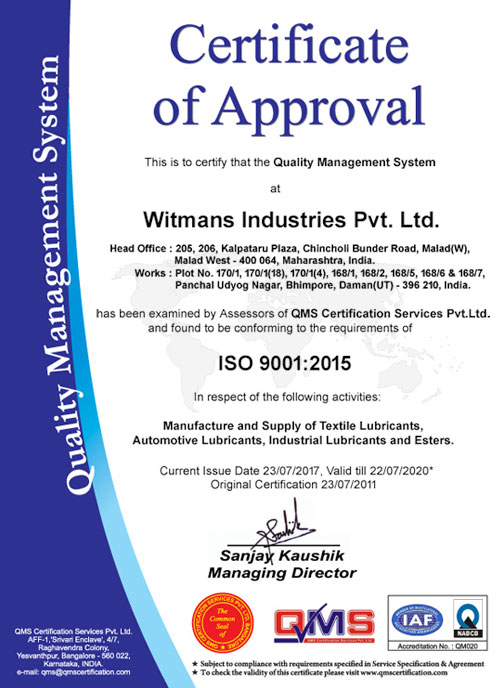

About Witmans

Witmans Industries PVT. LTD. is a one of the leading manufacturer and supplier of Specialty Chemicals in India since 1989. We offer products like specialty lubricants, process oils, plasticizers, industrial paints, spin finishes, and textile conning oils, including anticorrosive coatings and paints which are specially formulated materials applied to surfaces to protect them from corrosion. Corrosion, which is the gradual deterioration of metal due to chemical reactions with the environment, such as moisture and oxygen, can significantly reduce the lifespan of metal structures and equipment. Anticorrosive paints create a barrier between the metal surface and corrosive elements, preventing or slowing down the corrosion process.

These anticorrosive paints are manufactured by blending chemicals like resins, pigments, solvents, and additives in precise ratios. These components undergo thorough mixing, milling, dispersion, and filtration to ensure uniformity and desired properties such as adhesion and durability. We use world-class materials and advanced tools and technology to achieve this.

To learn more about our Anticorrosive Paints products, please contact us.

Other Products

Contact Details

CORPORATE OFFICE:

Address:

205 and 206, Kalpataru Plaza, Chincholi Bunder Road, Malad (West), Mumbai- 400064, India.

PHONE NUMBERS:

EMAIL:

Share this: