Conning Oil Additive Emulsifier

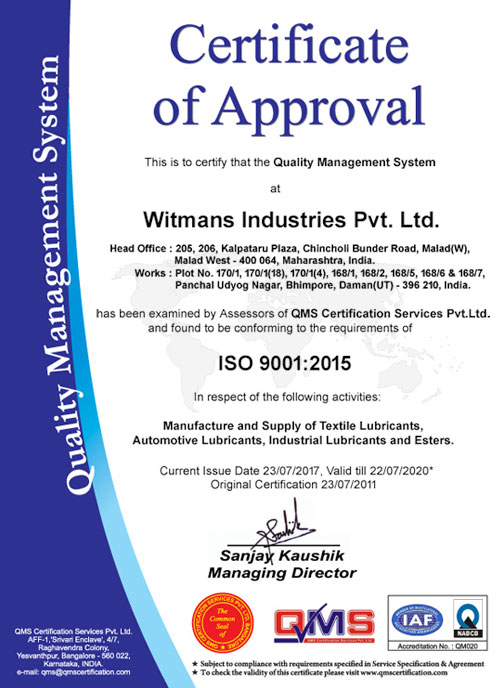

Witmans Industries PVT. LTD. is a one of the leading manufacturer and supplier of Specialty Chemicals in India. We offer products like specialty lubricants, process oils, plasticizers, industrial paints, spin finishes, and textile conning oils, including conning oil additive emulsifier which are a specialized additive used in textile industries to improve the lubrication and performance of conning oils during yarn manufacturing. It helps in reducing friction between fibers, preventing yarn breakage, and ensuring smooth yarn formation.

These emulsifier is manufactured by blending specific chemical compounds in controlled proportions, often including surfactants and lubricating agents, to achieve the desired properties and performance characteristics. The manufacturing process involves mixing the raw materials, homogenizing the mixture, and then packaging the final product for distribution to textile mills and yarn manufacturers.

| Product Details | |

| Density | 0.98 + 0.03 Gram per cubic centimeter(g/cm3) |

| Type | Conning Oil |

| Color | White |

| Use | Textile |

| Application | Industrial |

| Minimum Order Quantity | 10 Liter |

| Supply Ability | 1000 Liter Per Week |

| Delivery Time | 3-4 Days |

Technical Specification

| PROPERTIES | VALUES |

|---|---|

| Appearance | Clear To Slight Hazy Liquid |

| Colour | Light Yellow |

| Viscosity @ 40° C (Cst) | 75 ± 5 |

| Density @ 30° C | 0.985 + 0.02 |

| Flash Point °C | Above 200 |

| 10 % pH | 7 – 8 |

| Acid Value mgms of KOH / gms | Max. 20.0 |

Method Of Preparation:

Feed in kettle, 89% of Base Oil / White Oil wt/wt (viscosity as desired for final product). Add 10% of ‘Witcol CL-114’ wt./wt. under stirring for 30-60 minutes, until they are dissolved and you get clear liquid (agitator speed 60-70 rpm). Once you get a clear liquid, add 1% wt./wt. of TL-30 and stir for another 15-30 minutes (agitator speed 60-70 r.p.m.)

Note:

Before using ‘Witcol CL-114’, please ensure that it is a clear liquid. As the pour point is 15 ºC during winter, it may become hazy. If so, heat up to 40º C and stir well for 5-10 minutes to get a clear liquid.

| Product Details | |

| Density | 0.98 + 0.03 Gram per cubic centimeter(g/cm3) |

| Type | Conning Oil |

| Use | Textile |

| Application | Industrial |

| Minimum Order Quantity | 10 Liter |

| Supply Ability | 1000 Liter Per Week |

| Delivery Time | 3-4 Days |

Technical Specification

| PROPERTIES | VALUES |

|---|---|

| Appearance | Clear To Slight Hazy Liquid |

| Colour | Max 2.0/td> |

| Viscosity @ 40° C (Cst) | 55 ± 5 |

| Density @ 30° C | 0.98 + 0.03 |

| Flash Point °C | Above 200 |

| 10 % pH | 6-5 – 0.5 |

| Acid Value mgms of KOH / gms | 20.0 |

Storage Stability:

Approximately 12 months from the date of manufacturing.

Advantages:

It avoids splashing on texturising & twisting machines thereby reducing wastage.

Chemical Composition:

Polyalkylene polymer dissolved in mineral oil.

Technical Specification

| PROPERTIES | VALUES |

|---|---|

| Appearance | Clear Liquid |

| Odour | Odourless |

| Colour | Colourless |

| Viscosity @ 100° C (Cst) | 5000 ± 500 |

| Density @ 30° C | 0.83 + 0.02 |

| Flash Point °C | 160 – 180 |

Method Of Preparation:

Feed the mineral oil into the mixing vessel at room temperature. Add conning oil emulsifier package & stir well till a homogeneous mixture is obtained. After that add our antisplash additive, Witcol TL-30 & stir well to get a perfect antisplash conning oil.

Amount Of Application:

It is recommended to be used at a level of 1% in conning oil formulation to avoid splashing.

Storage Stability:

Approximately 12 months from the date of manufacturing.

Features

Enhanced Lubrication: Improves lubrication between fibers during yarn manufacturing process.

Reduced Friction: Minimizes friction between yarn and machine parts, reducing wear and tear.

Prevents Yarn Breakage: Helps prevent breakage of yarn strands, ensuring smooth yarn formation.

Improved Yarn Quality: Contributes to the production of high-quality yarn with consistent properties.

Compatibility: Compatible with various types of conning oils and yarn materials.

Stable Emulsification: Maintains stable emulsion in conning oils, ensuring uniform application.

Cost-Effective: Provides cost-effective solution for enhancing yarn manufacturing process.

Environmentally Friendly: Formulated to be environmentally friendly, with minimal impact on the environment.

Applications of Conning Oil Additive Emulsifier

Textile Industry: Used in spinning mills for lubricating fibers during yarn manufacturing process.

Yarn Production: Applied in conning oils to improve lubrication and reduce friction between yarn strands.

Synthetic Fiber Manufacturing: Utilized in the production of synthetic fibers such as polyester, nylon, and polypropylene.

Yarn Quality Enhancement: Helps enhance yarn quality by preventing yarn breakage and improving overall consistency.

Industrial Lubrication: Employed in various industrial lubrication applications where emulsification is required.

Machinery Maintenance: Used for lubricating machine parts to minimize wear and extend equipment lifespan.

Other Products

Contact Details

CORPORATE OFFICE:

Address:

205 and 206, Kalpataru Plaza, Chincholi Bunder Road, Malad (West), Mumbai- 400064, India.

PHONE NUMBERS:

EMAIL:

Share this: