Spin Finish Polypropylene

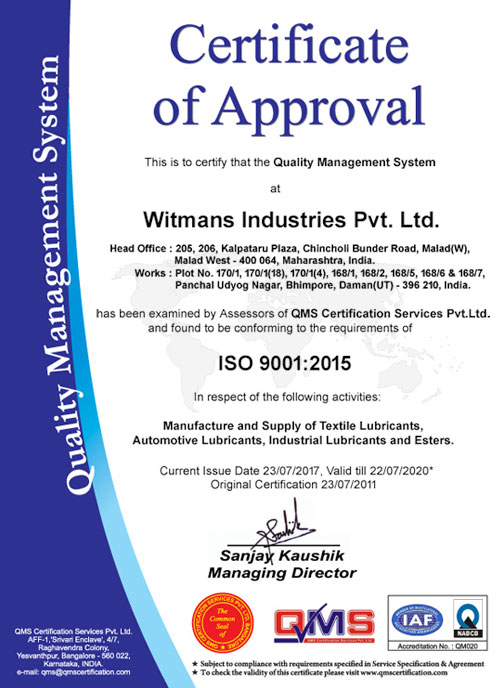

Witmans Industries PVT. LTD. is a one of the leading manufacturer and supplier of Specialty Chemicals in India. We offer products like specialty lubricants, process oils, plasticizers, industrial paints, and textile conning oils, including spin finish polypropylene which are a specialized coating applied to polypropylene fibers during production to enhance their processing characteristics.

It is manufactured by blending various chemical components such as lubricants, antistatic agents, and emulsifiers, which are then applied to the fibers during the spinning process.

| Product Details | |

| Density | 0.935 0.05 Gram per cubic centimeter(g/cm3) |

| Application | Industrial |

| Type | Polypropylene |

| Color | Multicolour |

| Minimum Order Quantity | 10 Kilograms |

| Supply Ability | 1000 Kilograms Per Week |

| Delivery Time | 3-4 Days |

Technical Specification

| PROPERTIES | UNIT | DESCRIPTION | SPECIFICATION |

|---|---|---|---|

| Appearance | Attribute | Visual | Clear Liquid |

| Colour (Gardner No.) | Number | ASTM D – 1544 | Max. 4.0 |

| Viscosity @ 40° (Cst) | CST | ASTM D – 445 | 50 ± 5 |

| Density @ 30°C | gm / cc | ASTM D – 1298 | 0.935 ± 0.05 |

| Appearance Of 10% Emulsion | Attribute | Visual | Translucent |

| pH Of 10% Emulsion | Number | ASTM D – 664 | 7.5 ± 0.5 |

| Active Content | % | ASTM D – 4377 | 90 ± 2 |

| Pour Point | °C | ASTM D – 97 | Max. 10°C |

Features

Lubrication: Provides lubrication to polypropylene fibers, reducing friction during processing.

Antistatic Properties: Helps control static electricity buildup in fibers, preventing static-related issues.

Enhances Fiber Performance: Improves fiber handling and processing characteristics.

Uniform Coating: Ensures uniform distribution of the finish on fibers for consistent performance.

Compatibility: Formulated to be compatible with polypropylene fibers and processing conditions.

Heat Resistance: Offers heat resistance during subsequent processing stages.

Moisture Control: Helps manage moisture content in fibers for optimal processing.

Environmental Stability: Maintains stability under various environmental conditions.

Ease of Application: Facilitates easy application during the spinning process.

Enhanced Product Quality: Contributes to the overall quality and performance of polypropylene-based end products.

Applications of Spin Finish Polypropylene

Textile Industry: Used in the production of polypropylene fibers for textiles such as carpets, upholstery fabrics, and clothing.

Nonwoven Fabrics: Applied to polypropylene fibers used in nonwoven fabrics for applications like medical textiles, filtration materials, and wipes.

Geotextiles: Utilized in the manufacturing of polypropylene geotextiles for applications in construction, landscaping, and erosion control.

Industrial Yarns: Applied to polypropylene yarns used in industrial applications such as ropes, nets, and conveyor belts.

Automotive: Used in automotive textiles and components made from polypropylene fibers, such as automotive upholstery and interior trim.

Packaging: Employed in the production of polypropylene-based packaging materials, including bags, sacks, and wraps.

Agriculture: Utilized in agricultural textiles and nets made from polypropylene fibers for applications like crop protection and packaging.

Filtration: Applied to polypropylene fibers used in filtration applications, including air filters, liquid filtration, and industrial filtration systems.

Construction: Used in construction materials such as geotextiles, insulation, and reinforcement fabrics made from polypropylene fibers.

Sports and Recreation: Employed in sports equipment and recreational products like ropes, nets, and outdoor textiles made from polypropylene fibers.

Contact Details

CORPORATE OFFICE:

Address:

205 and 206, Kalpataru Plaza, Chincholi Bunder Road, Malad (West), Mumbai- 400064, India.

PHONE NUMBERS:

EMAIL:

Share this: